Please see below our collection of ISPIRI wheels for MERCEDES, BMW, PORSCHE, RANGE ROVER, AUDI, V.W. and other various European and non-European cars.

Please refer to our guides on this page for a quick guide on what you need to know about wheels.

Παρακαλουμε οπως δειτε παρακατω την σειρα των ISPIRI ριμς/ζαντων μας για ολων των ειδων αυτοκινητων.

Παρακαλουμε οπως διαβασετε τους οδηγους μας για να ξερετε τι ειναι τα σημαντικα σημεια που πρεπει να γνωριζετε για τα ριμς σας.

Please refer to our guides on this page for a quick guide on what you need to know about wheels.

Παρακαλουμε οπως δειτε παρακατω την σειρα των ISPIRI ριμς/ζαντων μας για ολων των ειδων αυτοκινητων.

Παρακαλουμε οπως διαβασετε τους οδηγους μας για να ξερετε τι ειναι τα σημαντικα σημεια που πρεπει να γνωριζετε για τα ριμς σας.

NEW FFP1

|

NEW FFP2

|

NEW ISVR1

|

FFR1D

|

TECHNOLOGY

MOTIONCAST™ - THE PINNACLE IN CASTING TECHNOLOGY

ISPIRI FFR wheels are initially cast using the Ispiri Motioncast™ process, a superior form of casting that produces a denser alloy with less impurities and air pockets, allowing for a lighter and stronger wheel than traditional Low Pressure Cast wheels.

ISPIRI FFR wheels are initially cast using the Ispiri Motioncast™ process, a superior form of casting that produces a denser alloy with less impurities and air pockets, allowing for a lighter and stronger wheel than traditional Low Pressure Cast wheels.

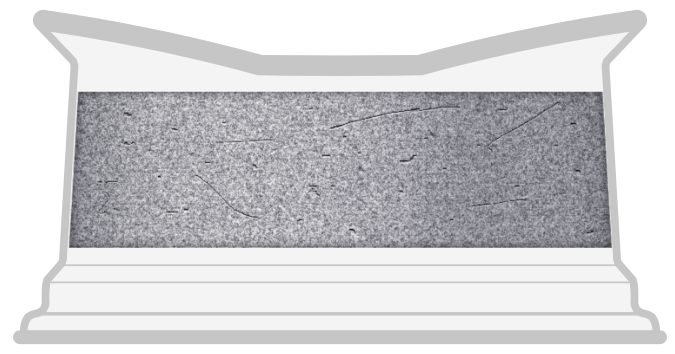

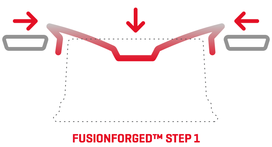

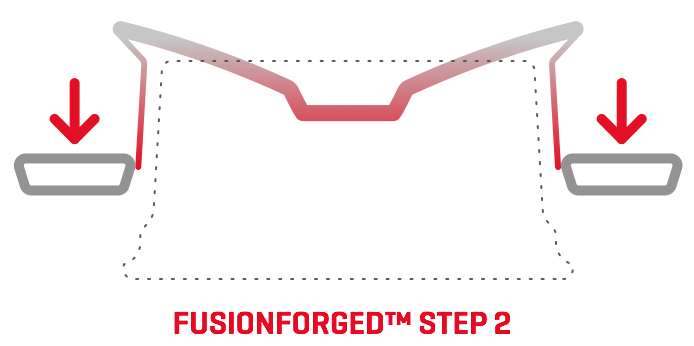

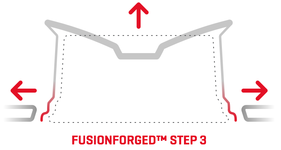

ISPIRI FLOW FORM TECHNOLOGYIspiri FusionForged™ utilises our state-of-the-art flow form technology. This process uses a special drum combined with heat and pressure applied by rollers that compress stretch and form the wheel barrel to a pre-defined thickness and desired profile.

This alters the structure of the aluminium forging a wheel barrel that is thinner, stronger and significantly lighter (approx 25%) than a traditional cast wheel, with enhanced strength and reduced weight properties comparable to fully forged wheels.

This alters the structure of the aluminium forging a wheel barrel that is thinner, stronger and significantly lighter (approx 25%) than a traditional cast wheel, with enhanced strength and reduced weight properties comparable to fully forged wheels.

|

Each wheel is transferred from an oven to the flow forming drum. High pressure rollers move into position at the top of the wheel barrel.

|

The rollers move down the barrel applying pressure to compress, stretch and form the heated wheel barrel.

|

Flow forming alters the structure of the aluminium to produce a wheel barrel that is thinner, stronger and significantly lighter than traditional cast.

|